| WHO'S DOING WHAT |

| CNG |

Ashok

Leyland Ashok

Leyland

Tata Motors

M&M

Maruti Udyog

Hindustan Motors

Bajaj Auto

Eicher |

| AUTO-LPG |

Tata

Motors Tata

Motors

Hindustan Motors

Maruti

Bajaj Auto |

| ELECTRICITY+ |

Bajaj

Auto Bajaj

Auto

M&M

Maini Automobiles

Ashok Leyland

+This involves direct charging of a battery by connecting to

the electric mains and not the production of electricity through

the use of hydrogen, which is dealt with separately |

| ETHANOL |

Tata

Motors Tata

Motors

M&M |

| BIO-DIESEL |

DaimlerChrysler DaimlerChrysler

Tata Motors

Mahindra (Tractors) |

| HYBRID ENGINES |

Tata

Motors Tata

Motors

TVS Motors |

| FUEL CELLS |

And

other hydrogen-dependent energy sources including metal hydrides And

other hydrogen-dependent energy sources including metal hydrides

Tata Motors

Bajaj Auto

M&M/IOC |

Suhas

Kadlaskar loves to drive. That's why he jumped at the prospect of

test-driving an experimental Mercedes Benz on his employer's Pune

test track. An experimental Merc? Well, it was actually a regular

silver-grey C 220 powered by an experimental fuel-bio-diesel. And

Kadlaskar is no daredevil test driver; he's the Finance Director

of DaimlerChrysler India. He put the car through its paces on a

sunny spring afternoon in March 2004... taking it up to 80-90 kmph.

Bio-diesel gave a smoother ride than the regular fuel, emission

was 70 per cent lower, and there was significantly lesser noise

and vibration. Soon, he was out on Pune's streets, criss-crossing

the city for an hour at a more sober 60 kmph. "We only changed

the fuel tank and the fuel pipe; the modifications cost only Rs

2,000," he says. And not once did the car stall or lose power.

The conclusion: Bio-diesel fulfils all the technical specs; the

question marks relate to the logistics of availability and price.

But more on that later.

A thousand kilometres away, in Faridabad on

the outskirts of Delhi, is the 65-acre R&D centre of Indian

Oil Corporation (IOC). Inside the lush green campus, scientists

are working in partnership with Mahindra & Mahindra (M&M)

to create the country's first hydrogen-powered vehicle. But the

production of pure hydrogen-the most plentiful element on earth-for

fuel is not easy. The gas is inflammable-and its production, storage

and transport present huge difficulties. "The problem is that

hydrogen likes the company of other elements, so the trick is to

find an inexpensive way of separating hydrogen from other gases,

and do it in large quantities," informs N.R. Raje, Director

(Research, Refinery and Development), IOC. The present method of

producing hydrogen from water through electrolysis is very expensive

and, therefore, not financially viable on a large scale. Similarly,

the production of hydrogen from solid biomass is also too expensive

to make mass production viable. (See How They Stack Up).

This quest is more than a mere academic search

for a motoring Holy Grail. Under a mandate from the National Hydrogen

Energy Board (NHEB), set up in February 2004 by the Ministry of

Non-Conventional Energy Sources, IOC will have to make available

10 per cent hydrogen-blended CNG fuel in Delhi, Mathura and Faridabad

by June this year, and gradually increase it to 100 per cent by

2008 for three-wheelers, buses and cars. The goal: Creating fuelling

infrastructure for over 1,000 vehicles by 2008. IOC's R&D centre

has already successfully tested 10 to 30 per cent hydrogen-blended

CNG fuel on Fiats and Ambassadors. "It's ddifficult, but do-able,"

says M.S. Ramachandran, Chairman, IOC, and a member of NHEB.

That's exactly what Kadlaskar feels about bio-diesel.

DaimlerChrysler's Indian subsidiary, in collaboration with the Council

for Scientific Industrial Research and Hohenheim University, Germany,

is spending Rs 3.5 crore on a pilot project to grow Jatropha Curcas

oilseed plants on two small plantations in Gujarat's Bhavnagar and

Orissa's Behrampur districts. No, it's not entering the Indian agriculture

sector. Yet. The vegetable oil extracted from Jatropha Curcas reacts

with alcohol in the presence of a catalyst to produce bio-fuel.

Two Merc C 220s that drove 5,900 km across the country using bio-diesel

reported an average mileage of 12-13 km per litre, the same as for

diesel. The fuel will enter Phase II tests in 2005-06: Mercedes-Benz

plans to drive 10 cars over 30,000 km of difficult mountainous terrain

to further test the fuel. But to really benefit from this breakthrough,

India will need to generate 2.62 million tonnes of Jatropha (to

ensure a mere 5 per cent blend with diesel) by 2007. That will mean

bringing 2.2 million hectares under cultivation. "A significant

number of farmers will have to come on board," informs Kadlaskar.

| Bio-diesel gives a smoother ride

than the regular fuel; emission is 70 per cent lower; and there

is less noise and vibration. The question marks relate to the

logistics of availability and price |

|

|

| Maini's Reva: The first |

Meanwhile, an exclusive team of engineers and

scientists at Tata Motors' Engineering Research Centres in Pune

and Jamshedpur is working on an ambitious project to develop a zero-emission

fuel cell-powered bus as well as a hybrid electric car. Also in

the works are a bio-diesel-fuelled Indica and a project-in collaboration

with IOC-to evaluate the impact of 7 per cent and 10 per cent ethanol

on LCV 79, a commercial vehicle, Sumos and Safaris. Ethanol is oil,

distilled from sugarcane in India, and corn and rapeseed in other

parts of the world, which can be used to power internal combustion

engines.

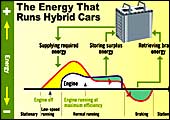

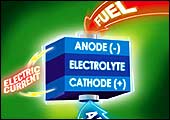

Commenting on the fuel cell-powered bus, V.

Sumantran, Executive Director, Engineering Research Centre, Tata

Motors, says: "The on-board fuel cell power system in the bus

harnesses the chemical energy stored in hydrogen and converts it

to electrical energy, which drives the motor. The benefits: No pollution

and reduced noise and vibration." Its other project, the hybrid

electric car-a prototype is expected to be ready this year-is expected

to revolutionise the car industry. "It will be 20 per cent

more fuel efficient and also have much lower emission levels,"

he adds.

| Hydrogen-powered fuel cells have

to overcome cost issues; ethanol and bio-diesel production are

too insignificant to make a difference; and electricity-driven

cars are still in their infancy |

|

| M&M's Bijlee: Another

electric vehicle |

Bajaj Auto has also jumped on to the alternative

fuel bandwagon. It launched ecorick, an electric battery-driven

auto-rickshaw, last month and hopes to sell around 1,200 vehicles

by September. "The new vehicle, which costs Rs 1.5-1.6 lakh,

is 50-60 per cent more expensive then the ordinary auto-rickshaw.

But over a five-year life cycle, it will be 10 per cent cheaper,"

says Tapan Basu, General Manager (Electric Vehicles), Bajaj Auto.

But the company will have to contend with difficulties related to

recharging of batteries, proper infrastructure and the higher initial

price. The company is trying to work around the first two problems

by tying up with petrol pump owners such as IOC, Bharat Petroleum

Corporation Limited and Hindustan Petroleum Corporation Limited

to store batteries, which auto-rickshaw drivers can use while their

own batteries are being charged. The company also plans to offer

this facility at Bajaj showrooms and at tyre shops owned by other

companies.

|

|

|

| The future is here: Bajaj

Auto's electric three-wheeler (top), and Ashok Leyland's hybrid

electric vehicle (below) |

But scientists at Bajaj Auto are really banking

on the production of metal hydride as a fuel for three-wheelers.

Metal hydride absorbs hydrogen and when heated it releases hydrogen,

which is released as a fuel. The project is still in the experimental

stage and a final breakthrough will take some years.

Other players like the Chennai-based Ashok Leyland

and M&M, too, want a piece of the action. The former has already

created the eco-friendly battery/diesel-operated Hybrid Electric

Vehicle. And as mentioned earlier, M&M is going full steam ahead

with its quest for a vehicle that runs on alternative fuels-despite

the failure of Bijlee, its expensive battery-operated three-wheeler.

If these trials bear fruit, they will go a

long way in ensuring India's oil security by reducing its dependence

on foreign oil, and also provide huge relief on the balance of payments

front. In 2003-04, the country's oil import bill was nearly Rs 80,784

crore. According to IOC's Ramachandran, India's dependence on foreign

oil is likely to rise to 85 per cent by 2025, against 70 per cent

now.

However, the Holy Grail is not yet in hand.

Hydrogen-powered fuel cells have to overcome cost and infrastructure

issues; ethanol and bio-diesel production are still too insignificant

to make a difference; and electricity-driven cars are still in their

infancy. Yet, as Tata Motor's Sumantran says, the future is pregnant

with possibilities.

|