|

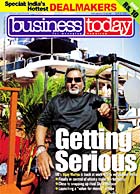

| Common ground: (L-R) Nadir Godrej,

MD, Godrej Industries; Nitin Anturkar; David Friedman; Debu

Bhattacharya; R. Sridharan, Deputy Editor, Business Today;

B. Muthuraman; R. Seshasayee; Ranajoy Punja and Mangesh Korgaonkar |

Last

year, china exported an estimated $540 billion (Rs 23,76,000 crore)

worth of manufactured goods. India, by comparison, managed a modest

$55 billion (Rs 2,42,000 crore). Don't lose hope, though. By 2015,

according to McKinsey estimates, exports of Indian-made goods

could soar to a staggering $300 billion (Rs 13,20,000 crore).

However, if that has to happen, Indian manufacturers will, first

of all, need to expand production capacity. But more importantly,

they will need to pull their technology up by the bootstraps.

Technology in product innovation and development, and technology

in manufacturing.

To get a sense of what's happening in Indian

manufacturing, Business Today invited some of India's biggest

manufacturers and experts to brainstorm on "How technology

can make Indian manufacturing competitive". Turning up on

the dot for the 8:00 a.m. Business Today Boardroom Breakfast session

in Mumbai were: B. Muthuraman, MD, Tata Steel; Debu Bhattacharya,

MD, Hindalco; R. Seshasayee, MD, Ashok Leyland; David Friedman,

President and MD, Ford India; Nitin Anturkar, Executive VP, taco

Engineering; Mangesh Korgaonkar, ICICI Chair Professor at the

Shailesh J. Mehta School in IIT Bombay; and Ranajoy Punja, VP

(Marketing), Cisco.

The panel moderator and BT's Deputy Editor,

R. Sridharan, kicked off the discussion by asking the speakers

to give a quick insight into what strategic objectives technology

fulfils at their respective organisations. According to Tata Steel's

Muthuraman, technology was important for two broad reasons. One,

to make the product globally competitive and, two, to bring newer

products and more value to the consumer. Citing Tata Steel's own

example, he talked about how, by going in for newer processes

despite the initial high cost of investment, the company was benefiting

from increased productivity today.

|

"There's

an inverse relationship between tariffs and technology inflow.

So, one has to own technology in critical areas"

R. SESHASAYEE

MANAGING DIRECTOR, ASHOK LEYLAND |

|

"Technology

is crucial to make your product globally competitive and enhance

value offering to customers"

B. MUTHURAMAN

MANAGING DIRECTOR,

TATA STEEL |

|

"Technology

is an enabler in making good products... (thanks to that)

the customer is no longer treated as a guinea pig"

DAVID FRIEDMAN

PRESIDENT & MANAGING DIRECTOR, FORD INDIA |

|

"We have

to focus on appropriate technology... the attitude of 'get

a good technology and it will solve your problems' won't do"

DEBU BHATTACHARYA

MANAGING DIRECTOR, HINDALCO |

|

"With

increasing prices and customers looking for cost reductions,

technology becomes important for survival"

NITIN ANTURKAR

EXECUTIVE VICE PRESIDENT, TACO ENGINEERING |

|

"While

Indian manufacturers have significantly improved on quality,

they still have a long way to go"

MANGESH KORGAONKAR

PROFESSOR, IIT BOMBAY |

|

"It's

not just about implementing technology, but the technology

has to be coupled with business innovation"

RANAJOY PUNJA

VICE PRESIDENT (MARKETING), CISCO SYSTEMS |

Taking on from Muthuraman, Ashok Leyland's

Seshasayee said that in the auto industry, technology was not

a differentiator but a qualifier. Yet, till the early 90s, he

pointed out, there was a lag between what the market wanted and

what the market got, since all technology-related decisions were

decided by somebody sitting in the corridors of power in Delhi.

And when the markets opened up, technology wasn't easy to access.

"I believe there is an inverse relationship between tariffs

and technology inflow," he said. How did Ashok Leyland cope

with the challenges? By making two critical decisions back then.

One was to develop technological skills on its own in critical

areas and, two, also leverage the collaborator's technology (Iveco,

in this case).

Moving away from what had been said so far,

Hindalco's Bhattacharya talked about instances when technology

doesn't work. Citing examples from Hindalco, he warned against

pursuing technology that weren't market-focussed. "The attitude

is, 'Get a good technology and it will solve your problems'-it

won't. We have to get technology and adapt ourselves and our processes

appropriately. Business should drive technology and not vice-versa,"

he said

Moving back to the automobile industry, David

Friedman of Ford India noted how things had changed from the days

when they would design a car and then hope manufacturing could

make it. Today, that was not the case. "Technology becomes

an enabler in making a good product. Not only does it contribute

to the design, but even the quality of inputs has improved due

to technology. For example, today cars don't rust," he pointed

out. In the olden days, the final customer did a lot of diagnosis

of identifying problems. Thanks to technology, that doesn't happen

any more. "We can check all of it scientifically. We no longer

treat the customer as a guinea pig," he said.

According to Nitin Anturkar of Taco Engineering,

technology is not a facilitator but a tool for survival. "With

increasing prices and customers looking for cost reductions, technology

becomes important for survival. Something as simple as reducing

cost and waste on shop floor involves tremendous amount of innovation,"

he said. Appropriate use of technology could also save unnecessary

capital expenditure, he noted. "Do we need a new plant when

we can improve productivity in the old one?" he asked.

Professor Mangesh Korgaonkar spoke about

his studies on what contributes to competitiveness of manufacturing.

While he was happy to note that Indian manufacturers had significantly

improved on quality, he felt that they had a long way to go in

terms of world-class quality. "At present, Indian manufacturers

don't score over 30 on a scale of 100 in terms of global capabilities,"

he said. Drawing comparisons with China, he said that Chinese

manufacturing had moved from factor-driven to investment-driven

advantage and thus would be harder to beat.

Cisco's Ranajoy Punja had the final word

in the discussion. He felt that for Indian manufacturing to be

competitve, it must understand market conditions, customer service,

etc. "It's not just about implementing technology, but the

technology has to be coupled with business innovation," he

said. A point Indian manufacturers would do well to remember.

|