|

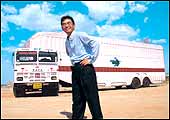

| Shinichi Mori, MD, Transystem Logistics:

Bringing JIT to India |

It

is a hot, dusty morning in early June, with the mercury nearly touching

the 40 degree celsius mark. But inside the cool environs of Metzeler

Automotive Profiles' India plant at Sahibabad in UP, 30-odd workers

are busy filling up blue plastic crates with weathered strips (beading

used in doors and widows of cars), although it is still not half-past

six in the morning. As the clock ticks inexorably, the buzz on the

3,700 sq. feet shopfloor reaches a crescendo. By quarter-to-eight,

nearly 100 boxes of the reusable crates have been packed for delivery,

and everybody sighs with a sense of relief. The first deed of the

day is over.

The rush at the Rs 48-crore company's Sahibabad

factory to beat the 8 am deadline is understandable, since the Transystem

Logistics International truck is at the doorstep and must leave

by 8.30 am. The full plastic crates are loaded onto the truck and

empty ones left behind, in what will be the truck's first leg on

its journey to the Toyota Kirloskar Motor's manufacturing unit in

Bidadi, 50 kms from Bangalore. Within hours of arriving at the Toyota

facility, the beadings in the bins will be fitted on waiting vehicles

in the assembly line. A perfect example of the Japanese "just

in time'' principle in action.

But the job's far from done for Ramesh Gautam,

the Manager at Metzeler, since he must inform the Transystem office

in Gurgaon and the Bidadi factory in Bangalore all the details of

the delivery, including the exact time of departure of the trucks.

After all, Metzeler's chances of continuing as a vendor to the world's

number three vehicle-maker depend on it meeting the strict schedules

each and every time.

|

|

| FROM DELIVERING

PARTS... |

...TO SHIPPING BUILT-UP VEHICLES |

| Transystem offers complete logistical

support to Toyota. |

Meanwhile, in Dundahera, three kilometres from

Gurgaon, K. Krishnamoorthy (Moorthy-san as he is called by his team

mates), in charge of the Transystem warehouse, is busy tracking

the truck from Sahibabad on his visual monitoring system to ensure

that it reaches his godown latest by 10.30 am. Similarly, he checks

on other trucks bringing in components for Toyota so that they can

be loaded onto bigger trucks in the night to continue on their five-day,

2,200-km journey to Bangalore. And as the trucks make their way

through a congested national highway, Krishnamoorthy will keep a

watchful eye over them till the parts have been unloaded at Bidadi.

Every day 261 such Transystem trucks log more

than a lakh of kilometres, picking up parts from Toyota's 83 vendors

in 20 different states to keep the Japanese auto giant's plant,

which works to clockwork precision, humming happily. Just how difficult

is Transystem's job? Consider that nearly 1,250 parts go into Toyota's

best-selling multi-purpose vehicle Qualis, of which 120 units are

manufactured every day. The tricky bit, however, is that Transystem

is the only transporter for Toyota, and if its trucks don't reach

on the hour every hour, Bidadi runs the risk of stopping its production

lines. Says Shinichi Mori, Transystem's Managing Director: "On-time

delivery of components is absolutely critical to our operation."

| Taking care logistical details is never easy,

and in India it's downright herculean |

So how does Transystem do it?

Logistical Leap

At the heart of Transystem's operations is

a fleet of 261 heavy trucks and 16 lighter ones that's managed by

a staff of just 45. The company, a joint venture between Transport

Corporation of India and Mistui & Co., maintains three cross-dock

facilities in Gurgaon, Chennai, and Pune. Toyota has 83 suppliers

(including original equipment manufacturers) in the four regions,

but a majority of them are near Bangalore and Delhi. On the 25th

of every month, Toyota sends out a detailed schedule to all its

vendors and Transystem, telling them of the raw material requirement

and daily production schedule.

|

"We are no longer

a company that just moves goods. We have truly become a logistics

company"

Vineet Agarwal/

Chairman/Transystem |

Based on the schedule, Transystem does "milk

runs" (See Transystem's Run) at each of the four regions, aggregating

the parts at the three cross-docks. Here, the components are loaded

on to a bigger truck, which then ferries it to Bidadi. All the parts

arrive "just in time" to be assembled. Delivering components

apart, Transystem ships built up vehicles to all of Toyota's 32

dealers in the country. It picks up spare parts from vendors and

drops them off at the dealers, and ferries imported knocked down

kits from Chennai port to the Bidadi plant.

Taking care of complete logistical details

is never easy, and in a country like India-with its poor road network

and notorious paperwork-it's downright herculean. And it doesn't

matter if-like Transystem's Indian promoter, the Transport Corporation

of India-you are a Rs 600-crore-a-year fleet operator, with 3,000

trucks and more than 1,000 branches spread throughout the country.

For instance, the trucks from Delhi must negotiate 30 toll gates

before they reach Bidadi.

What makes the job harder still for Transystem

is that it must live up to Toyota's demanding production system.

It essentially involves producing the right type of unit (vehicle

or part), in the right quantity at the right time. The idea, of

course, being to lower costs and meet the end-customer's delivery

schedule. For instance, the only inventory that Toyota maintains

provides for contingencies, and does not serve as a buffer. Even

Toyota's suppliers like Metzeler maintain only two days' inventory,

although in the case of other carmakers the stock is typically more.

Says Vineet Agarwal, Transystem's 29-year-old Chairman: "You

need military-like discipline to meet Toyota's punishing schedule."

Perhaps that's one reason why convincing Toyota

to outsource its crucial logistics piece to Transystem was not easy.

It took three extended trips to the Toyota headquarters in Tokyo,

innumerable meetings with delegations from Toyota and Mitsui, and

a "hell of a lot of convincing over six months" before

Toyota would say yes. The deal was finally struck in April 1999-two

years before Toyota went into production-and TCIL roped in Mitsui

to create Transystem with an initial investment of Rs 28 crore.

Says a senior official of Toyota Kirloskar: ''Inventory costs are

down from Rs 49 crore to Rs 32 crore in the last two-and-a-half

years. We intend to reduce this to Rs 22 crore in the next 18 months.''

| Transystem has ensured that it learns from

the experience of Toyota and Mitsui |

Despite the apparent risk, having a single supplier

in Transystem means less hassle for Toyota. For one, it doesn't

have 30 suppliers jostling at the factory gate to pick up or deliver

goods. Moreover, since most of the time suppliers are not sure when

the goods will be unloaded, they are forced to maintain a warehouse

close to the plant. All this means that more time and money is spent

than need be.

Transystem, on its part, has ensured that it

learns as much from the global experiences of Toyota and Mitsui.

For example, the sequence in which components are loaded on its

trucks mimics the sequence in which the parts will be assembled

on the shopfloor. This not only saves time in terms of segregation,

but also lowers packaging costs and damage to the components. Similarly,

Transystem workers handling Toyota's final product-the cars-have

to wear special clothes to avoid scratching car paint, and the cars

themselves are shipped in special covered trucks to avoid vandalism.

And to ensure that the special trucks do not return empty from the

dealers, Transystem picks up cars of other companies.

Such small innovations have helped the joint

venture grow from Rs 30 crore in 2001 to Rs 40 crore in 2003. By

2008, Mori wants to make it a Rs 150-crore company. He just may.

For one, Toyota has been renewing the contract every year for the

last four. Says Agarwal: "This association has virtually changed

the mindset of the company. We are no longer a company that just

moves goods. We have truly become a logistics company." Thank

Toyota.

|