|

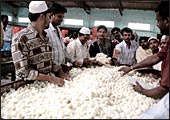

| White gold? Poor quality of cocoons

is a common lament among reelers at the auction house |

OCTOBER

10, 2006

11 a.m., Government Silk Market, Ramanagaram,

South Karnataka

On

the face of things, there shouldn't be any cause for concern over

the state of the local silk industry in Ramanagaram, a small town

on the congested Mysore Road, some 50 km from the bustling technopolis

that is Bangalore. The government-run silk market and auction

house is a beehive of activity, as farmers bring in their cocoons

and patiently wait for an auction to be completed and their produce

to be auctioned to reelers from the neighbouring localities. Assistants

sling large sacks of cocoons onto their heads and stagger out

of the market to nearby reeling units. It is estimated that some

50 tonnes of cocoons, valued at Rs 60 lakh, are traded every day

and more than 7,000 people (across farming, reeling, and other

operations) are employed in the local silk industry. Government

officials, including B.C. Kempegowda, the Deputy Director of Sericulture,

are quick to intercept this writer at the entrance of the silk

market, insisting on giving us (the photographer follows close

behind) a guided tour of this facility and "helping out"

with any other requirements.

|

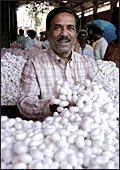

| Hard work and minimal returns: Many

reelers are reported to have moved to Bangalore or other jobs |

India currently is a distant second to China

in the global silk market, producing some 16,000 tonnes of silk

annually, with over 60 per cent of this amount coming from units

in Ramanagaram and other small towns in Karnataka. "Ramanagaram

is the silk capital of the country and this is the largest silk

market in Asia," Kempegowda says over a piping hot glass

of almond (badaam) milk in his corner office. Outside, however,

the mood is not so genial, as farmers and reelers claim that the

government is interfering too much with prices and facilities

are inadequate at this market. "The quality of cocoons is

very poor at this market, since farmers are greedy and want to

dump their produce in this market. You need at least a week for

the cocoons to mature, but they bring it here in two-three days

itself," says Pyaare Jaan, a local reeler. Farmers, however,

are quick to retaliate, contending that reelers and their buyers

lower prices, creating artificial surpluses or claiming that cocoons

are of inferior quality. "Prices can vary from Rs 130-140

per kg on one day to Rs 90-100 the next," says one aggrieved

farmer.

At Naalbanwadi Mohalla, the sense of discontent

is evident, with some former reelers reportedly reduced to daily

wage earners in Bangalore and others resorting to running kiraana

stores or scrap yards. "We would like the government to take

a more active role to help the industry," says one farmer.

Government officials admit that as larger towns such as Bangalore

and Mysore offer more lucrative opportunities, an involuntary

migration seems inevitable.

|

|

| The government view: Kempegowda (above)

blames the recession on failed monsoon |

|

|

Kempegowda, however, insists that the government

has a handle on things and hasn't let the situation spiral out

of control. "There was a recession two-three years ago when

the monsoons failed and the entire industry went through years

of struggle," he tells this correspondent as we walk through

the section selling pale yellow multivoltine grade, towards the

snow white (higher quality) bivoltine variety. An industry struggling

to recover from a near fatal recession over the last couple of

years (according to some unofficial estimates, 500 of the 2,000-odd

reelers in town shut shop) means that banks are saddled with debts

of at least Rs 5 crore and are unwilling to lend any more. "Reelers

over-stretched themselves four years ago and when the downturn

hit, many of them defaulted on their loans," an official

with the local State Bank of India branch claims. Because of these

defaults, many of the reelers have remained saddled with outdated

production equipment that has only widened the chasm between them

and their Chinese counterparts. "Ramanagaram is just about

managing to survive today, but urgently needs to upgrade to semi-automatic

or automatic reeling equipment and larger production facilities

to stay competitive," says M. Imitiaz Pasha, Proprietor of

SIM Silks and the President of the Local Reelers Association.

Aside from internal problems, Ramanagaram's

silk industry has been affected by dumping by Chinese manufacturers.

"Dumping has affected this industry tremendously over the

last 18-24 months and only the imposition of a stiff anti-dumping

tax has helped recently, since it brought prices to near parity,"

claims Kempegowda. The issue of dumping gets some high-profile

support, with Karnataka's Chief Minister and, incidentally, the

local MLA, H.D. Kumaaraswaamy, promising to lend a helping hand

to the industry. "Because of dumping by Chinese players,

our silk industry has been hit hard. My government is taking all

measures possible to help sericulturists, be they mulberry farmers,

silk twisters, yarn traders or silk producers," says Kumaaraswaamy.

Meanwhile, Kempegowda points out that expansion

and modernisation plans are afoot for the Ramanagaram Silk Market

and work will proceed as soon as the green signal is received.

"We have sent the government a Rs 50-crore development plan

for this market and hope to receive their approval soon,"

he claims. Part of this amount, will be used to expand the existing

auction space and to set up automated machines (on the lines of

an ATM) to deliver cash to farmers," says Kempegowda. While

the 5,000-year old silk industry has managed to rapidly convert

itself from a cottage industry into a large-scale operation, it

remains to be seen which silk route Ramanagaram's units take.

|